6 Different Types Of Silk In India

From Production to Consumption: The Significance of Silk in India's Economy

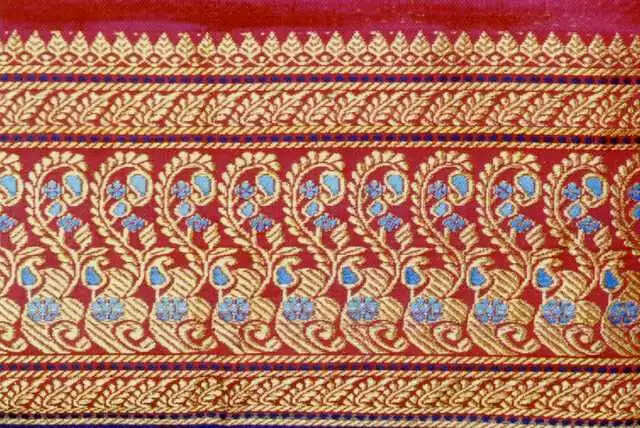

In India, the definition of luxury is silk. Without being wrapped in magnificent silks, our momentous occasions and celebrations are not complete. The fabric's shine gives the wearer an air of elegance and a regal appearance. Our weddings are nothing less than a silk-inspired fashion show, with the bride and groom and the majority of the guests wearing every variety of silk imaginable. Silks are a crucial component of many other festivals. Thus, it should come as no surprise that we are both the leading consumers and producers of silk worldwide. The industry must credit Indian women for their taste in and appetite for silk since they account for more than 75% of this consumption in the form of Silk Saris.

Despite its high aspirational value, silk only accounts for a modest portion of the world's textile manufacturing. Types of silk are closely related to the area from which they are produced. With its distinctive weaves, patterns, and designs woven from silk yarn made by a variety of silkworms, each location has its own speciality. Typically, we associate the origins of silk with those locations: Banarasi, Kanchipuram, Dharmavaram, Paithani, etc. These are the geographical indications, and the majority of our silk items are marked with them, but we shall discuss them another time. Let's examine the various varieties of silk produced in India and their origins.

What is Silk?

On the surface, silk comes from silkworms and cotton comes from cotton plants, the two natural fabrics. Let's see how silkworms produce this luxurious fabric for us.

Technically speaking, a caterpillar known as a "silkworm" secretes fluid proteins that are then spun into silk. Knowing what these silkworms eat is crucial to understanding the many types of silk. They eat a variety of plants and leaves.

Silk, a natural insulator derived from animal protein, aids in keeping the body cool in hot weather and warm in cold weather.

Lifecycle of a Silk Worm

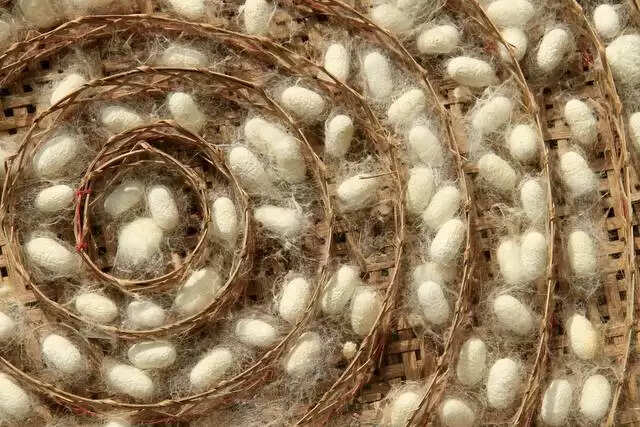

A silkworm typically goes through four stages in its life cycle: egg, caterpillar, pupa, and moth. When it is a caterpillar, it spins its cocoon. We humans gather the filament created in this way to use as the main component of our silks.

During springtime, female silk moths engage in an annual activity of laying up to 300-500 small, dot-like eggs. Upon being subjected to warmth, these eggs hatch into worms that feed on a bed of leaves for about a month. Within a few days of reaching maturity, the caterpillars begin weaving their cocoon using their body protein and rigorous movements. The cocoon serves as their protective cover during a crucial life stage and appears like a soft cotton ball woven with a single thread. Once the weaving is complete, the caterpillar enters a motionless Pupa state. At this stage, they may either be boiled to extract silk or allowed to develop into moths, starting the cycle anew after mating.

The filament produced by silkworms is not readily usable and requires multiple processing steps before it can be utilized. The cocoons are collected and boiled to eliminate the gum and separate the filament, which is a single thread measuring a few hundred meters in length, held together by a natural gum known as sericin.

The process of raising silkworms for the purpose of silk production is called sericulture. One of the major obstacles faced by sericulture entrepreneurs is ensuring that their silkworms are not affected by any infections or diseases that could adversely impact their yield.

Natural Color of Silk

The color of the silk filament is determined by the hue of the leaves ingested by the silkworm. The natural color of silk is a prime example of the adage 'you are what you eat', with the filament's shades of beige ranging from off-white to light brown, and various tones in between, all depending on the silkworm's diet. These natural-colored filaments are subjected to washing, cleaning, bleaching, and dyeing in a variety of colors according to the weaver's or patron's creative needs.

In the past, natural colors were predominantly derived from plant sources such as flowers, woods, seeds, berries, bark, roots, and even nuts. The blue color was obtained from indigo leaves, red hues from Madder berries, yellow from turmeric, marigold flowers, or cow urine, while green was obtained by blending blue and yellow, and orange shades from saffron. Although natural colors had a limited range, they were well-suited to our skin and posed no environmental risks. However, with the advent of chemical dyes, the variety of available shades has increased exponentially, and the dyeing process has become faster and more efficient due to the ease of mixing and creating colors with chemicals.

The dyed threads are then spun using traditional and modern methods in a process known as reeling. Once this process is completed, the thread is ready to be woven using different weaving techniques, creating an enchanting interplay of threads.

Different Types of Silk in India

Two key factors determine the type of silk produced - the silkworm species and the leaves that they consume prior to commencing the cocoon-weaving process. Mulberry and Non-Mulberry Silk are the two primary categories of silk.

Mulberry Silk

Mulberry silk, which is derived from Bombyx mori worms feeding on mulberry leaves, is the most prevalent type of silk, accounting for up to 90% of global silk production. India is the world's second-largest producer of Mulberry silk. This silk has a natural shine, softness, and smoothness that is typically associated with silk fabrics. Mulberry plants are grown specifically for their leaves in a process known as Moriculture, with around 500 grams of leaves being required to sustain a single caterpillar throughout its life. When you do the math, it's easy to see why silk produced by these caterpillars can endure for more than a century. Mulberry silk is lightweight, durable, and has a natural shine.

Vanya Silk – Wilder Types of Silk

In India, Non-Mulberry silk is available in three primary forms, namely Tussar, Muga, and Eri, which are collectively referred to as Vanya Silk. This variety of silk is considered slightly wilder in nature, hence the name Vanya, which stems from the word "Vana," meaning forest or wild. Silkworms that produce this type of silk feed on wild plants, which is evident in the yarn they spin - the color and texture vary, resulting in a final fabric with a unique, exotic appearance. This type of silk has a slightly raw texture and non-uniform consistency. The wild cocoons are harvested from forests by tribes residing in close proximity, who subsequently hand weave the silk.

Tussar silk

The Tussar silk is sourced from the central region of India, specifically from the states of Jharkhand, Chhattisgarh, West Bengal, and Bihar. This variety of silk, which belongs to the Vanya silk category, is the most prominent and highly favored among silk enthusiasts. The Antheraea moth species feeds on forest wild plants to produce this type of silk.

Eri Silk

Eri silk is produced by Samia Ricini and Philosamia ricin worms, and is primarily sourced from the local Assamese region where it is called Era or Castor. These worms feed on castor plant leaves and spin an open-ended cocoon, which is harvested only after the worms have hatched. This results in an irregular and uneven weaving pattern, making Eri silk a natural Ahimsa silk. In addition to this, Eri silk is also famous for its thermal properties that make it an ideal fabric for keeping warm.

Muga Silk

The silk is produced by the Antheraea assamensis silkworm, which is semi-domesticated and feeds on fragrant Som and Sualu leaves. It is mainly produced in Assam and has a yellowish-green color, making it a preferred choice for weaving Chadors and Mekhalas. The silk has been mentioned in many ancient Indian texts, such as the Ramayana, and was supported by the Ahom rulers of the region.

Ahimsa Silk

Ahimsa silk is a type of silk that is manufactured without boiling the cocoons. This method enables the larvae to hatch and break open the cocoon, resulting in the single long filament breaking into multiple small pieces. These small pieces must then be spun together to form a lengthy yarn, which contributes to the silk's higher cost. Despite this, the resulting yarn is still the same silk as before, but it is processed after the moth emerges from the cocoon.

Where are these types of Silk Produced in India?

Asia dominates global silk production with over 95% of the total output, primarily driven by China and India. In the 2020-21 fiscal year, India produced 33,771 metric tonnes of silk yarn, with major contributions coming from the southern and northeastern regions of the country. The states of Karnataka, Andhra Pradesh, Jharkhand, and Assam are key players in India's silk industry.

India is divided into five silk zones, each comprising several states, for the production of different types of silk. These zones are numbered as:

- Karnataka, Andhra, Tamil Nadu, Maharashtra, Telangana, Kerala – 66% of silk production

- Uttar Pradesh, Chhattisgarh, MP, Rajasthan, Gujarat

- Jharkhand, West Bengal, Odisha, Bihar – About 10% of silk production

- Jammu and Kashmir, Uttarakhand, Himachal, Punjab, Haryana

- Assam, Meghalaya, Manipur, Nagaland, Tripura, Arunachal, Mizoram, Sikkim – 22% of silk production

Distinctive silk clusters are present in these regions, each featuring unique weaves, patterns, and color preferences. For instance, Banaras is known for Tanchoi and Jamdani, Deccan for Paithanis, and Bengal for Balucharis.

Silk Farming

In India, silk farming is an important cottage industry that provides employment to more than seven million people in 59,000 villages spread across 25 states, with women comprising about 60% of the workforce. Despite the rise of industrialization, the industry has remained intact and is poised to play a vital role in building self-sustaining local economies in India. Silk enjoys great cultural significance in the country, which translates to consistent consumer demand. This demand is efficiently met by skilled silk farmers, weavers, and fashion designers who produce high-quality handcrafted and handwoven silks.

Currently, the demand for silk in India surpasses its production capacity, leading to a need for importing silk. However, this presents an excellent opportunity for modern entrepreneurs to expand the production of raw silk, explore innovative ways to use silk, and merge this timeless heritage with future lifestyles.